What is a Cosmetic Bottle?

Aug 08, 2025

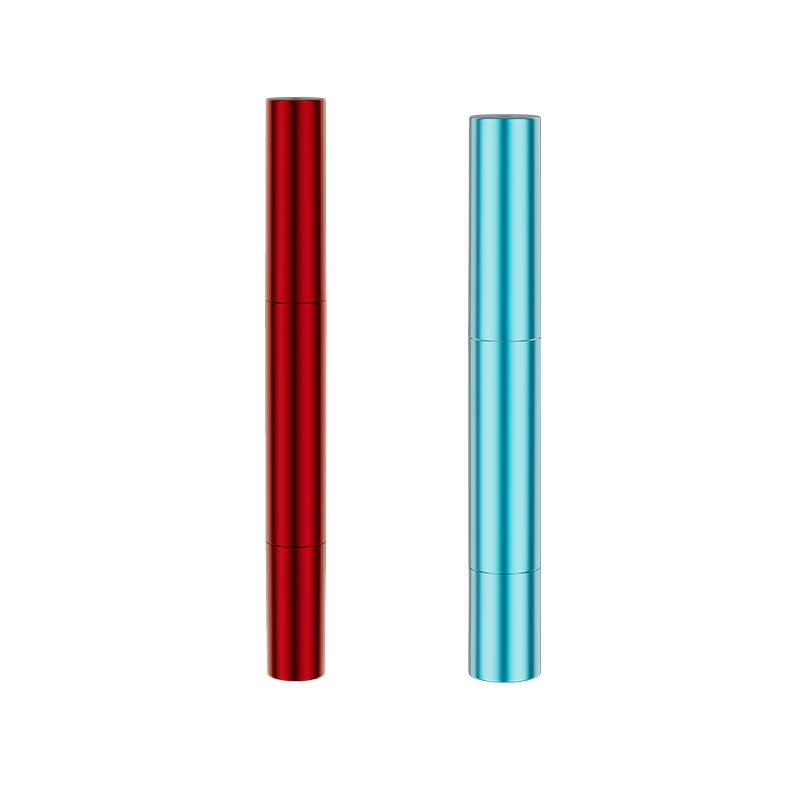

1. Diverse Shapes and Sizes

Cosmetic Bottle come in a variety of shapes and sizes to suit different cosmetic formulas and brand needs. From cylindrical to square, tall to short and stout, a wide range of designs are available. These diverse shapes and sizes not only meet product capacity requirements but also enhance the product's visual appeal and user experience. Ningbo Yiziman Cosmetics Technology Co., Ltd. carefully considers these factors during the design and production process, ensuring that each cosmetic bottle perfectly meets customer needs.

2. Premium Material Selection

Cosmetic Bottle are made of high-quality materials to ensure product safety and durability. Glass and plastic are common material choices, each with its own unique advantages. Glass bottles are known for their durability and chemical resistance, making them suitable for storing a variety of cosmetic formulas, while plastic bottles are popular for their lightweight and cost-effectiveness. Ningbo Yiziman Cosmetics Technology Co., Ltd. meticulously selects materials to ensure that each cosmetic bottle provides optimal protection and user experience.

3. Enhance Brand Image

The design and material of a cosmetic bottle not only protect the cosmetics inside but also enhance the product's overall value and brand image through its appearance. Both transparent glass and stylish plastic bottles lend a premium and sophisticated feel to the product. Ningbo Yiziman Cosmetics Technology Co., Ltd. pays close attention to detail and offers a variety of surface treatments, such as UV printing, heat transfer, hot stamping, spray coating, and electroplating, to ensure the cosmetic bottle aligns with the brand's aesthetic and market positioning.

Why Choose Ningbo Yiziman Cosmetics Technology Co., Ltd. Cosmetic Bottle with Vacuum Pump System?

Ningbo Yiziman Cosmetics Technology Co., Ltd., founded in 2018, is a leading Cosmetic Bottle supplier and cosmetics bottle company in China. Whether you need standardized packaging materials or personalized solutions, the company has rich experience and flexibility to ensure your product stands out. Choosing Ningbo Yiziman Cosmetics Technology Co., Ltd.’s Cosmetic Bottle with a vacuum pump system has several key reasons:

Keeping the Product Fresh

- Sealed Environment: Cosmetic Bottle with a vacuum pump system can create a sealed environment, preventing air from entering the bottle during dispensing. This minimizes contact between the product and oxygen.

- Anti-oxidation Protection: The vacuum pump system avoids the degradation of cosmetic formulas over time due to oxygen exposure, ensuring consumers get high-quality products from the first to the last use.

- Extended Freshness: By maintaining the freshness of the product, the vacuum pump system ensures that cosmetics remain in their best condition and efficacy throughout use.

Enhancing Product Protection

- Anti-pollution Design: In addition to preventing oxidation, the vacuum pump system provides excellent anti-pollution protection, avoiding exposure of the product to bacteria, dirt, and other impurities during use.

- Hygienic Sealing: Traditional packaging methods can easily lead to product contamination, while the vacuum pump system maintains the hygiene and seal of the product, reducing the risk of microbial growth and spoilage.

- Improved Safety: The vacuum pump system minimizes pollution risks, ensuring that the products consumers use are always safe and reliable.

Precise Dispensing, Controllable Dosage

- Uniform Dosage: The vacuum pump system can achieve precise dispensing and controllable dosage of cosmetics, with the pump mechanism outputting a uniform and consistent product dose each time.

- Avoiding Waste: There is no need for excessive pumping or squeezing, avoiding product waste and ensuring consumers can easily dispense the appropriate amount of product.

- Enhanced User Experience: Precise dosage control allows consumers to better control the amount of product used, avoiding overuse and maximizing the value and lifespan of the product.

Reducing Product Waste

- Direct Dispensing Design: The vacuum pump system dispenses the product directly from the bottle, avoiding exposure of the remaining formula to the air, which helps reduce product waste.

- Avoiding Spillage and Contamination: Traditional packaging methods often lead to product waste due to over-dispensing, spilling, or contamination, while the vacuum pump system effectively avoids these issues.

- Full Utilization of Product: Consumers can use up all the product without affecting its quality or freshness, thus minimizing waste and maximizing product value.

Advantages of Ningbo Yiziman Cosmetics Technology Co., Ltd.

Rich Experience and Flexibility

- Standardized and Personalized Solutions: Ningbo Yiziman Cosmetics Technology Co., Ltd. has rich experience and flexibility to provide standardized packaging materials and personalized solutions, meeting the needs of different customers.

- Innovative Design: The company focuses on innovation, continuously introducing new Cosmetic Bottle designs and functions, ensuring that products remain at the forefront of the industry.

- Rapid Response: With its strong production capacity, Ningbo Yiziman Cosmetics Technology Co., Ltd. can quickly meet the requirements for batch production or custom needs, ensuring high-quality and stable products.

Strict Quality Assurance

- ISO 40001 Certification: Ningbo Yiziman Cosmetics Technology Co., Ltd. has ISO 40001 certification, demonstrating its commitment to environmental responsibility and quality assurance, giving customers confidence.

- WCA Factory Inspection: The company's WCA factory inspection further ensures the quality and safety of the products, allowing customers to choose its Cosmetic Bottle with peace of mind.

- Attention to Detail: The company pays attention to details, providing a series of surface treatment technologies such as UV printing, thermal transfer, hot stamping, spraying, and electroplating to ensure the products meet the standards.

Strong Production Capacity

- Over 3 Million Packaging Units per Month: Ningbo Yiziman Cosmetics Technology Co., Ltd. has a production capacity of over 3 million cosmetic packaging units per month, capable of meeting large-scale production needs.

- Efficient Production Process: The company uses advanced production equipment and efficient production processes to ensure the high quality and stability of Cosmetic Bottle.

- Flexible Production Arrangement: Whether for batch production or custom needs, Ningbo Yiziman Cosmetics Technology Co., Ltd. can flexibly arrange production to ensure timely delivery.

Through the above detailed analysis, it can be seen that choosing Ningbo Yiziman Cosmetics Technology Co., Ltd.’s Cosmetic Bottle with a vacuum pump system not only enhances the protection and user experience of the product but also brings higher market competitiveness and consumer recognition to the brand through its high quality and innovative design.

English

English 中文简体

中文简体