What are the basic functions of cosmetic packaging?

Oct 17, 2025

Basic Functions of Cosmetic Packaging

1. Product Safety

Protecting cosmetics from damage by external factors such as light, oxygen, and humidity, thereby extending their shelf life.

Using high-quality plastic materials and in conjunction with the company's ISO40001 environmental management system, we ensure packaging safety throughout the entire production and use chain.

2. Ease of Use and Portability

Ergonomically designed pump heads, spray nozzles, or screw caps enhance the user experience.

Ningbo Yiziman's production line can produce 3 million sets per month, quickly meeting the demand for high-volume, lightweight packaging.

3. Information Communication and Brand Display

The packaging surface can be processed using a variety of processes, including UV printing, heat transfer, hot stamping, spraying, and electroplating, to accurately display brand logos and product information.

High-quality visual presentation helps consumers quickly identify product attributes.

4. Complying with regulatory and environmental requirements

WCA factory inspections ensure that packaging materials comply with domestic and international cosmetics regulatory standards. Using recyclable materials and complying with ISO40001 demonstrates a company's commitment to environmental responsibility.

How can cosmetic packaging design enhance brand recognition and achieve differentiation?

1. Unique Structural Design

Utilizing innovative bottle shapes and unique opening and closing methods, the packaging is instantly recognizable on the shelf.

Ningbo Yiziman boasts flexible customized production capabilities, enabling rapid small-batch trial runs to validate design effectiveness.

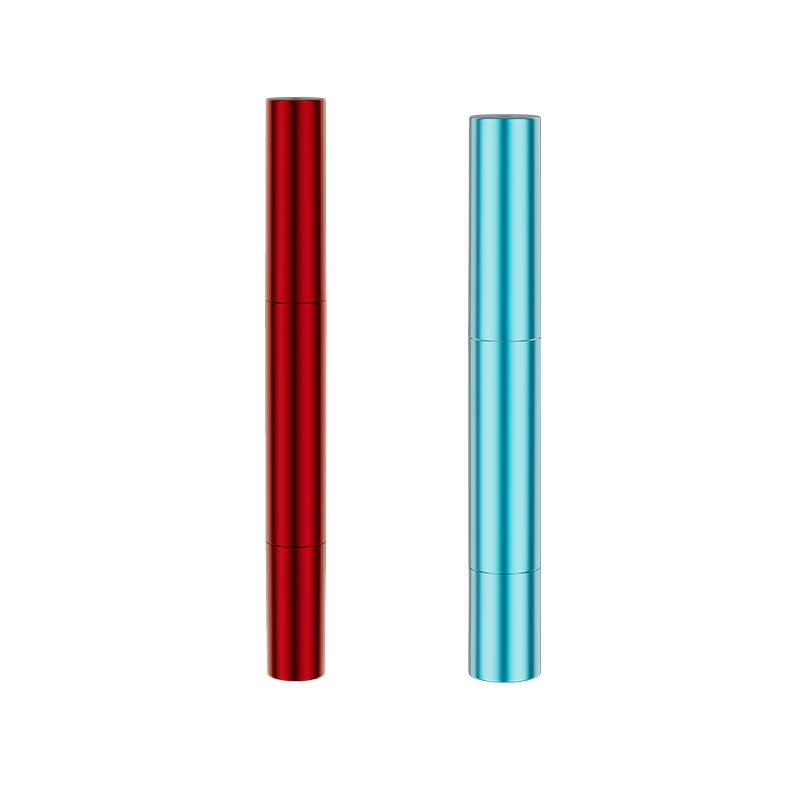

2. High-End Surface Finishing

Using hot stamping, UV printing, and spray coating to enhance the packaging's gloss and texture.

Electroplating creates a metallic finish, enhancing the premium brand image.

3. Color and Pattern Consistency

Combining the brand's primary colors with iconic patterns creates a visual identity (VI).

The company provides precise color management and print calibration to ensure consistent color across each batch of packaging.

4. Functional Innovation

Adding anti-counterfeiting labels, QR codes, or NFC chips enables information traceability and interactive marketing. Thermal transfer technology embeds anti-counterfeiting patterns onto packaging surfaces, enhancing brand credibility.

English

English 中文简体

中文简体